Innovation Unleashed: Design Thinking

- Entech Innovative

- Feb 9, 2024

- 4 min read

The term “Design Thinking” at Entech Innovative Engineering extends far beyond aesthetics, embodying an approach that prioritizes user-centric solutions and problem-solving. Our methodology centers around understanding the unique needs and challenges of our clients and end-users, while also understanding the need for safety and reliability on the wholistic side as well for the benefit of all parties. Creating practical solutions to complex issues is our specialty.

Highlighting an example of this is our work on the KSC Heroes and Legends exhibit. We were challenged with designing, fabricating, and installing a walkway ramp and canopy that resembles the mighty X-15 plane.

For the KSC Heroes and Legends walkway ramp canopy the “Design Thinking” came when Falcon’s Treehouse (now Falcon’s Beyond) had a unique concept for how to get the guests from the outside and into the new exhibit. When they came to Entech to have further technical conversations with Justin Stehr, Lead Engineer (now Executive Director) there was a high level of conversation of what material this would be built out of.

Justin recalls 3 main materials being discussed: Concrete, Fiberglass (FRP), and Aluminum. Each material was heavily discussed and through various challenges with each:

Concrete would need to have a lot of labor at the site consistently and need to be replicated to make sure uniformity was in the pour was going to present a challenge especially should something go wrong the mistakes would be costly in time and money.

FRP would need to be studied with precise engineering as the variety of layup schedule would be a challenge when it comes to meeting the coastline hurricane wind loads. As well as molds would need to be made and when developing FRP parts the Molds can be a major cost driver.

Aluminum seemed at the time to make the most sense with the need to look like aviation why not use what would look most like what is needed. Once again, the challenge would be dealing with the coastal wind loads and needing a high thickness of a piece of metal and the pure size of that needing to be bent brought challenges that did not seem worthy of what was going to be needed.

Figure 1: Behind the Scenes Look Initial White Board Concept Drawings and Conversation Wind Loads

Once the decision was made to pursue FRP as the most promising option, two primary objectives were initiated to underscore this "Design Thinking" approach and highlight what distinguishes Entech from other companies. The first objective involved Justin and Chief Engineer John Marhoefer guiding the FRP department in developing a ½” thickness FPP layup capable of meeting yield and ultimate breaking strength requirements. (Refer to Figure 2 for the "breaking" image.)

Figure 2: Breaking Failure Point

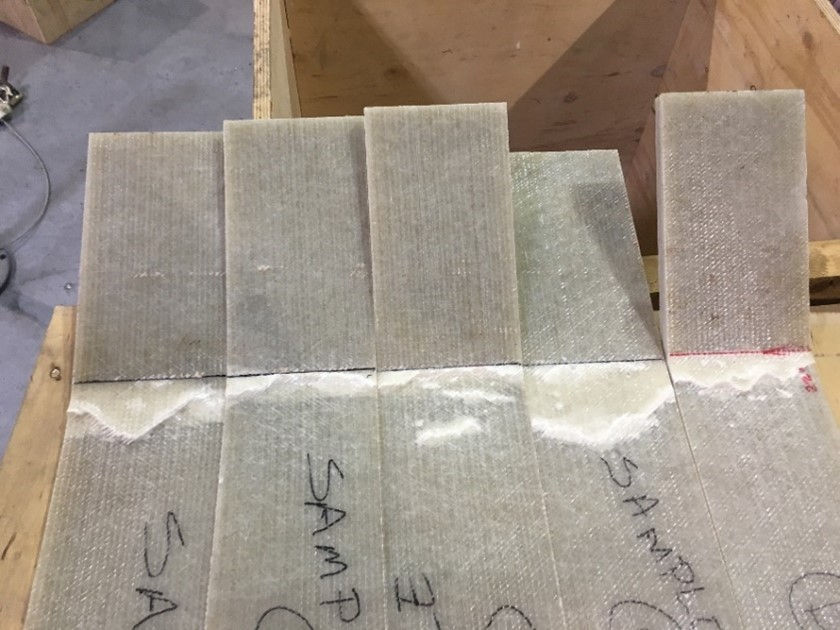

To get an accurate measurement, 10 coupons were made of five varieties of layup schedules and then they were tested by pulling a load of 0-200lbs by increments of 20lbs and checking the deflection each increment. (See Figure 3 for test set up)

Figure 3: Sample Load Testing Setup

After multiple tests were completed a “secret” formula of Gel Coat, 1.5OZ Chopped Mat, Layers of 1708 and Fire Rated Resin created the FRP part that would meet standards to build. (See Figure 4 for visual inspection)

Figure 4: Sample Review of Final Deflections

While this was going on, the other major challenge to conquer was to make sure this could be done with minimal amounts of Molds required. Justin reflects on this challenge, stating “When I was sent over the model it was difficult to grasp how the helical portion of the ramp had any relation to make this out of 2-3 molds let alone one.” After a variety of trials and errors within SolidWorks, Justin saw where things could come together using 1 mold for the straight pieces and 1 other mold for the helical section. With both these significant obstacles overcome, the project could advance confidently, as the customer was assured that budget and schedule targets would be met, while ensuring the safety and reliability of the structure for the Space Coast.

Figure 5: Lifting the Part from the Straight Mold

Another aspect of "Design Thinking" crucial to this project often overlooked is the logistics of transporting large items to the site. I am sure all of us have seen the “oversized load” trucks on the road - Shipping regulations and the complexities of moving oversized loads come with significant costs and challenges. Without careful consideration, unforeseen expenses can severely impact a company's bottom line. In this case, specialized crating resembling a "quarter pipe" for skateboarding was designed to ensure the shipment adhered to regulations and avoided costly permits, highlighting the foresight and attention to detail crucial to maintaining Entech's margins.

Figure 6: Model of the “Shipping Crate”

To wrap up, the essence of "Design Thinking" at Entech Innovative Engineering extends beyond superficial aesthetics, embodying an approach that prioritizes user-centric solutions and problem-solving. Crafting practical solutions to complex issues is our forte, as evidenced by our work on the KSC Heroes and Legends exhibit. Overcoming significant obstacles such as material selection and mold efficiency with innovative solutions, we ensured that the project progressed confidently, meeting budget and schedule targets while guaranteeing the safety and reliability of the structure for the Space Coast. Through our commitment to innovation and attention to detail, we continue to redefine excellence in specialty engineering.

Comments